Fire sprinkler systems are an innovation that has been saving property and lives for over a century. Modern-day fire sprinkler systems are significantly more sophisticated, complex, and effective than their earlier counterparts, and massive systems now protect large hospitals, warehouses, schools, and more.

Yet, if the water pressure and flow running through these sprinkler systems are not sufficient, they can be rendered utterly useless.

This is where fire pumps play an important role.

What are Fire Pumps?

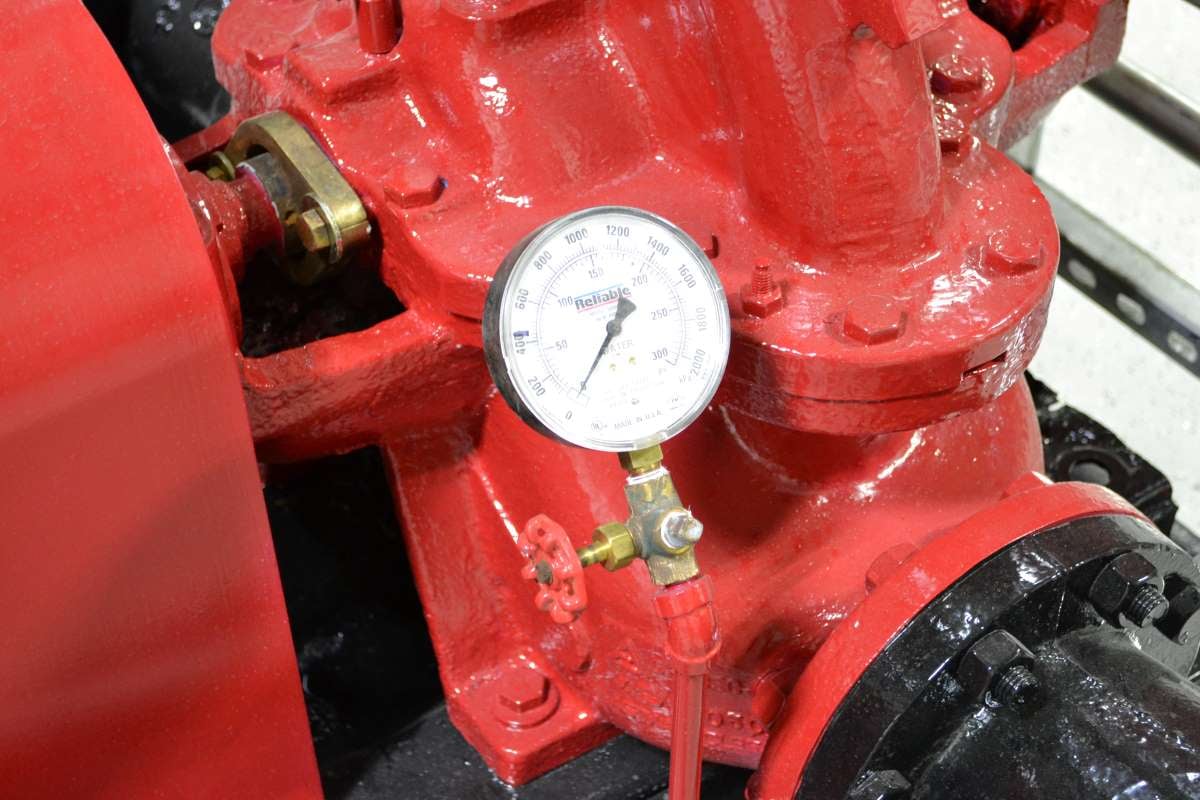

Fire pumps are an integral piece of life safety equipment used to help fire sprinklers maintain the proper pressure and flow rate necessary to protect property effectively.

Fire pumps are kept in designated pump rooms or houses. They are powered typically by either an electric or diesel-powered engine, though there are a few steam-turbine-powered pumps.

The pumps are designed to activate when a predetermined loss of pressure occurs in the fire sprinkler system. Typically, the activation of one sprinkler head is not enough to activate the fire pump. However, if two or more fire sprinkler heads activate, the loss in pressure to the system will, in most cases, be enough to activate the fire pump.

Once activated, it begins to pump water into the fire sprinkler system to ensure the water flows at a sufficient rate and pressure to suppress and extinguish the fire effectively.

Fire pumps are designed with both water flow and water pressure in mind, as both rate-of-flow and pressure are essential factors in ensuring the water effectively suppresses the fire. Most fire pumps can pump up to 5,000 gallons of water per minute, and some up to 600 PSI of water.

Electric vs. Diesel Powered Fire Pumps

While electric and diesel-powered fire pumps deliver essentially the same results, their engines operate differently and require different protocols for maintenance and testing.

Electric motor-powered engines are a cheaper option and are slightly more common. They require less maintenance and inspections, which is another perk. However, if there is no backup generator, the pump is rendered useless if the power goes out, which is a serious disadvantage and will likely also mean the fire sprinkler system itself is of no use.

That said, some applications, such as hospitals and schools, require that a backup generator be used in conjunction with an electric fire pump, in which case, power outages should not be an issue.

Diesel-powered fire pumps do not have the disadvantages of being affected by power outages and are generally more reliable. However, they are much more expensive and require an annual maintenance protocol to keep them in good working condition.

Are Fire Pumps Required?

The answer to this question is: It depends.

The sprinkler system design will determine whether or not a fire pump is required. Once a sprinkler system is designed and installed, it receives a water-flow test. If that test demonstrates insufficient gallons per minute (flow) or water pressure to meet the sprinkler system demand, the designers must include a fire pump in the application. The fire pump provides the additional PSI and/or gallons per minute necessary to ensure the sprinkler system can operate effectively.

The cause for the insufficient water pressure or flow varies, but it often has something to do with a low water pressure supply from the water’s source, whether it be the local public utility or a nearby pond engineered for supplying water to the fire safety system.

In theory, then, a sprinkler system may not require a fire pump in one location, but a sprinkler system of similar size and complexity may require a fire pump at a different location.

Fire Pump Inspection & Testing Requirements

All pump houses and fire pumps require weekly visual inspections to check on the pressure, suction, and discharge, and to ensure that all the valves are in the open position, the fire pump controller is in a normal state, etc.

Both electric and diesel-powered pumps must also be no-flow or dry tested. This must be done weekly for diesel-powered pumps, while electric-powered pumps usually require dry-testing only once every month for ten minutes. However, certain electric applications do require weekly dry tests as well.

Both the weekly visuals and the weekly/visual dry tests can technically be performed

by the property’s regular maintenance personnel, as long as they have been trained on what to look for and how to perform the tests. However, many customers still elect to have Koorsen Fire & Security come out to perform these inspections and tests, as it decreases their liability.

Finally, fire pumps must also undergo full annual testing that puts the whole system through its paces, using actual water, and this testing must be performed by a licensed professional.

During the tests, the technician will measure water pressure and water flow and then compare the measurements to the fire pump’s original design specifications to ensure it’s operating effectively.

When discrepancies are found, there is often an easy explanation and repair that can be made to correct the problem, such as when a clog is discovered or a simple piece of hardware needs to be replaced.

Additional Maintenance

Diesel-powered fire pumps must be serviced annually in addition to the inspections and tests. This maintenance includes changing fuel filters, testing batteries, fluid levels, oil filters, etc. Maintenance must be performed by someone certified to work on diesel engines for fire pump application, not just a regular technician.

As fire pumps are easily $50,000-$60,000 pieces of equipment, you do not want just anyone running these annual inspections and maintenance protocols on your fire pump.

This is why Koorsen makes it a practice of sending specialized technicians out to inspect, test, and work on fire pumps during their annual testing and maintenance. Koorsen’s training center has two in-house electric fire pumps to train on, and every aspect of service and repair is taught and practiced in the training center before a technician ever goes out into the field. You can rest easy when a Koorsen technician arrives to care for your fire pump.

Have More Questions?

At Koorsen, we pride ourselves on providing the very best and most accurate service and information possible. If you have additional questions about your current fire pump or a possible future fire sprinkler system and pump, give us a call today. We would be happy to talk with you to answer your questions or send one of our highly-trained technicians out to take a look.

Don’t wait. Give us a call or go online today!