What is a CO2 Fire Suppression System?

A CO2 fire suppression system uses carbon dioxide to suppress or extinguish a fire. Due to the dangers of carbon dioxide (CO2) to humans, CO2 fire suppression systems are typically used in areas where there are few or no personnel working. These sensitive areas include engine rooms, generator rooms, power stations, and flammable liquid storage rooms.

CO2 fire suppression systems share many of the same basic parts as clean agent fire suppression systems like cylinders, nozzles, and release devices. Due to the extreme dangers of CO2 though, CO2 fire suppression systems also use many additional life safety devices and parts to reduce the risks of CO2 exposure.

What are the Life Safety Parts of a CO2 Fire Suppression System?

A CO2 fire suppression system is designed to flood the protected space with around a 34% CO2 concentration to effectively suppress the fire. At 7.5% concentration, CO2 can cause asphyxiation to humans. Below are some of the life safety devices and parts that you will find on a CO2 fire suppression system to reduce the risks of CO2 exposure to personnel.

- Pneumatic Time Delay: When the CO2 fire suppression system is activated, a pneumatic time delay is first initiated. The pneumatic time delay works from the pressure of the CO2. The time delay operates for 30 or 60-seconds in order to allow personnel to evacuate before discharging the CO2.

- Pneumatic Siren: The pneumatic siren is first activated by the pneumatic time delay and creates an audible warning that the CO2 fire suppression system is activated. The pneumatic siren will continue to go off during the CO2 discharge as well. Only when all of the CO2 has been discharged, will the siren go silent.

- Supervised Lock-Out Valve: Whenever general maintenance is being performed, personnel can activate the lock-out valve to prevent accidental discharge of CO2. The lock-out valve is activate by turning a lever which effectively closes off the line between the CO2 cylinder/s and the discharge nozzles. The lock-out valve is monitored at the control panel to ensure the valve is reopened and in operating condition after maintenance has been performed.

- Pneumatic Wintergreen Odorizer: CO2 is a colorless, odorless gas that is undetectable by humans. To ensure personnel are aware that CO2 has been discharged or that the system is leaking CO2, a pneumatic wintergreen odorizer is added to the system. The odorizer injects a small amount of wintergreen scent into the CO2 agent as it flows out of the system. Personnel that work around or near the CO2 fire suppression system should be instructed that when the wintergreen scent is detected, that there is carbon dioxide gas in the area and to evacuate immediately.

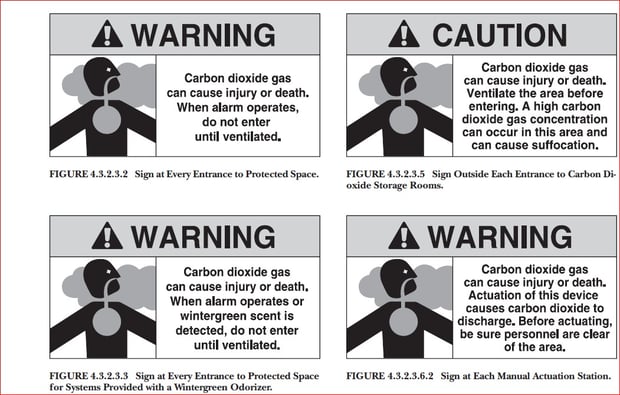

- Warning Signs: In NFPA 12, Standard on Carbon Dioxide Extinguishing System, Chapter 4.3.2, it states that warning signs shall be affixed in a conspicuous location in every protect space; at every entrance to protected spaces; and in spaces near the protected spaces where carbon dioxide could migrate, creating a hazard to personnel. Signs state that carbon dioxide gas can cause injury or death. They also mention that when alarm operates or wintergreen scent is detected, to not enter protected space until fully ventilated.

Have More Questions About CO2 Fire Suppression Systems?

To learn more about CO2 fire suppression systems and how they can help protect your business, contact Koorsen Fire & Security today. Our fire suppression experts can help answer any questions you may have about CO2 and other types of fire suppression systems. Koorsen has extensive experience in designing, installing, inspecting, and maintaining fire suppression systems for businesses in all industries.